Advisory company establishes local massive mining centre of excellence for EMEA region

My first exposure to underground mining was in the early 1990’s at Thabazimbi iron-ore sublevel cave section. It was hard not to be fascinated by the three-dimensional labyrinth of tunnels filled with busy load-haul-dumpers constantly loading ore from draw points and feeding ore passes. Additional to the sublevel cave, alternative methods such as open stoping and vertical crater retreat were being investigated on a trial mining basis to cater for the changes in shape, dip and quality of the ore body as the sublevel cave was nearing the end of its economic life.

The technical department worked closely with the production team to understand and manage factors such as the shape of the drift roof, the width of the drift, the difference in fragmentation of the blasted ore and the caved roof, the inclination of the front, grade control processes for dilution management, and meticulous ring and blast design. I can remember the general interest with the available international technical papers on advanced, high-production caving operations such as Kiruna, an iron-ore mine in Sweden.

Underground mining was doing well in South Africa from the deep gold mines, the shallower platinum mines and a number of mines using massive mining and caving methods such as Thabazimbi, Prieska, Nkomati, Finch, Koffiefontein, Cullinan, Black Mountain and many more. Later, the Palabora open pit transitioned to block caving and, more recently, mines such as Ivanhoe’s Platreef and the De Beers’ Venetia mine are establishing large-scale mines, using massive mining methods.

Based on this experience, and on the back of the strong Southern African advisory services industry, our mining advisory company, Ukwazi, participated in the design and establishment of a number of underground mines, using massive methods across Africa, particularly the west African gold mines and the high-grade copper mines of the Copperbelt.

A Rich History of Underground Mining

Since the discovery of the kimberlitic diamonds at Kimberley and the Witwatersrand goldfields in the latter part of the 19th century, mining has played a significant role in South African society. This was later cemented by the discovery of the platinum group metals of the Bushveld Igneous Complex by Lombaard and Merensky in the 1920’s. To supply energy and metals to these mines and related local industries, coal deposits were developed in the Eastern Cape, Kwazulu-Natal and Mpumalanga; copper and iron-ore was targeted in the Nort West province, Limpopo and the Northern Cape. Every one of these discoveries had an impact on the world-wide supply of saleable minerals.

Before long, surface mines started to transition to underground mining. This is where South African companies really pioneered technologies and methodologies to deal with the complexities of underground mining. Based on this, South Africa was internationally recognised as a centre of excellence for underground mining. Despite the flat-dipping, narrow tabular nature of the gold and platinum deposits of the Witwatersrand and the Bushveld Igneous Complex, our underground mining methods and technologies were diverse. As part of this trend, we were developing large block caves, large sublevel caves and the world’s deepest shafts, world-class infrastructure and process facilities based on a wide range of commodities.

To build these mines and industries, large, highly skilled and multi-disciplinary technical teams were developed over the years, some of which were later unbundled to operate independently. A number of world-class advisory companies were started to deliver niched technical skills to the mining industry over the last 50 years. Ukwazi is one such company and is part of this evolution in underground massive mining techniques.

The recent growth of the international consulting industry has centred around the development of international reporting codes and guidelines and the ability of the north American and Australasian public funding institutions to secure a platform for investors and access to funding for mining houses world-wide, and also in Africa.

A Strategic Response to Industry Evolution

As mining activities on the African continent mature, some of these deposits must transition to underground mines and some are more suitable to underground mining methods from the start. Most of these underground mines will be developed based on massive mining and caving methods.

For mining executives, this transition represents one of the most significant strategic choices they will face, not only in terms of the envisaged underground operation, but also the management of the transition and the potential production gap, if not planned on an integrated basis.

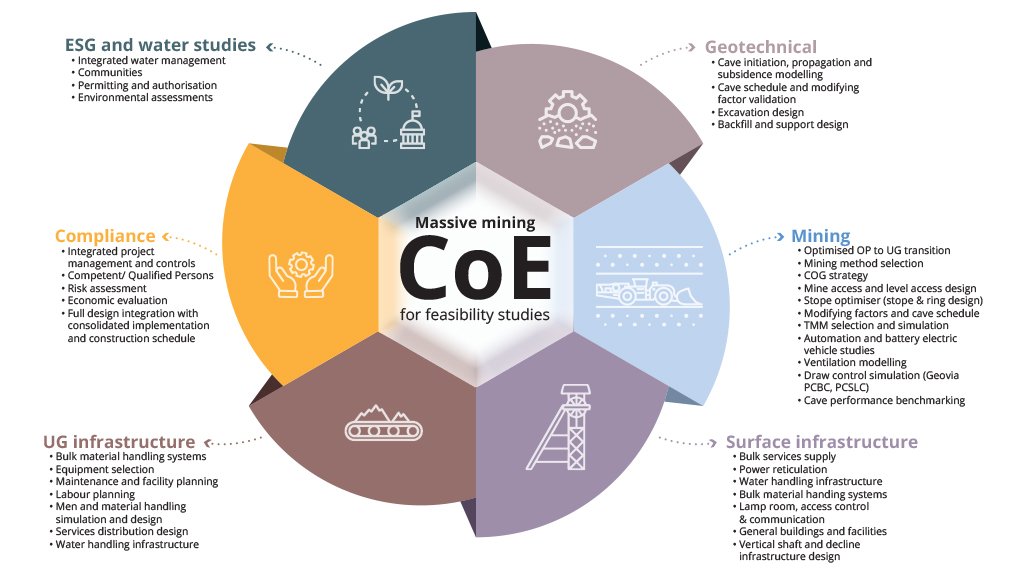

Recognising this fundamental shift, Ukwazi established a local underground massive mining Centre of Excellence (CoE) in 2025, bringing together world-class expertise to guide mining companies through this complex transformation. The experts in our CoE understand the financial, operational and regulatory implications of this decision and can provide the technical foundation as a basis for informed decision-making.

Through comprehensive feasibility studies, risk assessments and operational planning, the CoE helps clients understand not just whether underground mining is viable, but how to optimise its approach for maximum value creation. This support extends throughout the project lifecycle, from initial concept through full production and integrated mine closure.

Addressing Industry-Wide Challenges

The establishment of this CoE comes at a time when the mining industry faces unprecedented challenges. Stakeholder expectations around environmental stewardship have never been higher, while the technical complexity of accessing deeper ore bodies continues to increase.

Massive Mining Technical Excellence for Africa, from Africa

The Centre’s integrated approach recognises that successful underground mining operations require seamless coordination between geological understanding, ESG, geotechnical test work, simulation and benchmarking, surface and underground engineering infrastructure design, practical mining considerations, risk management and compliance reporting. By bringing together specialists across these disciplines, the CoE provides comprehensive solutions that address the full spectrum of underground mining challenges. The structure of our massive mining CoE was based on the incremental skills and decades of practical experience that are unique and specific to underground massive mining and caving projects. Our integrated approach is illustrated in the graphic above.

Innovation Through Collaboration

Beyond individual project support, the CoE serves as a hub for innovation in underground mining practices. The collaborative environment enables specialists to share insights across different styles of mineralisation, mining methods and geotechnical conditions, fostering the development of new approaches and technologies. This knowledge-sharing culture ensures that clients benefit not only from individual expertise but from the collective engagement of the entire team.

Our specialists regularly engage with world-wide subject matter experts, equipment manufacturers and technology providers to stay at the forefront of underground mining innovation. This network approach ensures that clients have access to the latest technological advances and can implement cutting-edge solutions in their operations.

As the mining industry across Europe, the Middle East and Africa (EMEA), and specifically Africa, continues to evolve, the importance of specialised underground massive mining expertise will only grow. The establishment of this CoE represents a significant milestone in Ukwazi’s evolution and in the industry’s ability to access deep mineralised deposits sustainably and efficiently.

The Centre’s integrated approach, combining deep technical expertise with collaborative innovation, positions it as an essential resource for local and international mining companies navigating the complex environment of medium- and large-scale massive mining underground projects.

The mining industry’s future lies beneath the surface, and this initiative is uniquely positioned to guide that journey. Through our specialised expertise, practical experience, innovative approaches, and unwavering commitment to industry advancement, the CoE represents a new chapter in underground massive mining excellence.

Supporting Strategic Decision-Making

Ukwazi is an independent, multi-disciplinary mining advisory company with a 21-year track record in delivering code compliant, cohesive, and integrated mining and mine infrastructure studies across the EMEA region.

Based on our rich history of underground mining, specifically massive mines for diamonds, iron-ore, copper and gold mining and our locality in Africa, we are well positioned to continue to add significant value to massive mining and caving projects throughout the EMEA region.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation